Why US Manufacturing and Industrial Companies Are Hitting a Wall

Let’s be honest. If you’re running a business in the USA industrial sector right now, you’ve probably noticed things feel different from what they did two years ago.

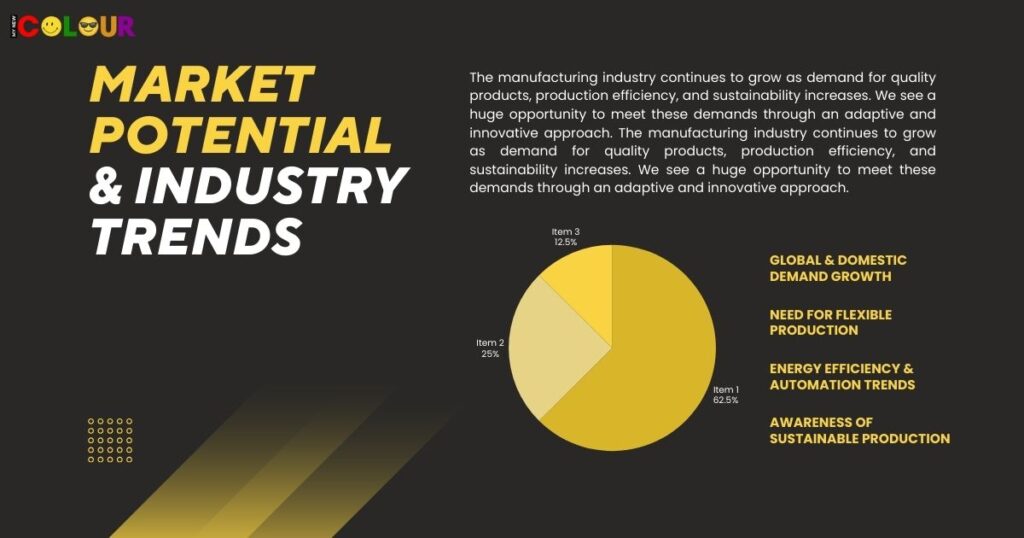

The American manufacturing industry is facing a strange moment. On one hand, we’re seeing some of the most advanced technology ever introduced to factory floors. On the other hand, many businesses are dealing with slower growth, rising costs, and constant pressure to do more with less.

Here’s what the numbers show: Industrial production growth USA has been inconsistent. According to Federal Reserve data, manufacturing output grew by only 0.2% in late 2024, much lower than the 3-4% growth rates we saw in 2021-2022. Business activity slowdown USA is real, and it’s affecting everyone from small machine shops to major automotive plants.

The problem isn’t just one thing. It’s a combination of high interest rates making expansion expensive, workforce challenges with skilled labor shortages, and global competition that never sleeps. Many factory owners I’ve talked to say they’re stuck between investing in new technology and managing day-to-day cash flow.

Then there’s the supply chain issue. Even though things are better than the chaos of 2020-2021, US supply chain resilience is still being tested. Companies that relied on just-in-time delivery are now keeping more inventory, which ties up cash. Others are reshoring production, which sounds great but means higher labor costs.

The industrial market USA is also dealing with changing customer demands. Everyone wants faster delivery, custom products, and lower prices. That’s a tough combination to deliver without significant changes to how you operate.

Agitate: The Cost of Standing Still Is Higher Than Ever

Here’s what keeps business owners up at night: the competition isn’t waiting.

While you’re trying to figure out if you can afford new equipment, your competitor might already be using AI adoption in manufacturing to cut their production time by 30%. They’re using smart manufacturing USA technologies that predict machine failures before they happen, saving thousands in downtime.

Let me give you a real example. A mid-sized automotive parts supplier in Michigan was running the same production setup they had for 15 years. It worked fine. But when a competitor started using automation in US factories and could deliver the same parts 40% faster, they started losing contracts. Within eight months, they had to lay off workers and lost two major clients.

The Industrial Internet of Things (IIoT) isn’t science fiction anymore. It’s happening right now. Factories are connecting machines, tracking every metric, and using that data to make better decisions. Companies using these systems report 20-25% improvements in efficiency.

But here’s the hard part: digital transformation in industry requires upfront investment. You need new equipment, software, training, and often consultants to help you through it. For many businesses, especially smaller ones, that feels impossible when margins are already tight.

US logistics and warehousing demand is also shifting. Amazon and other e-commerce giants have trained customers to expect next-day delivery. If you’re in distribution, you either invest in better warehouse technology and faster systems, or you lose business to someone who will.

The workforce issue makes everything harder. Skilled workers who understand both traditional manufacturing and new technology are hard to find. Many experienced workers are retiring, and younger workers often prefer office jobs over factory work. This creates a gap that’s expensive to fill.

Solution: Smart Steps Forward That Actually Work for Real Businesses

Good news: you don’t have to transform everything overnight. The most successful companies in the US industrial sector are taking smart, measured steps.

Start with one process. Instead of trying to automate your entire operation, pick your biggest bottleneck. Maybe it’s quality control, packaging, or inventory management. Focus your digital transformation in industry efforts there first. A food processing company in Ohio did this with their packaging line, using sensors and AI to reduce errors by 45%. The ROI is paid for the system in 14 months.

Use data you already have. Most factories generate tons of data but don’t use it. Start analyzing your current production data to find patterns. You don’t need fancy IIoT systems at first—even basic data analysis can reveal where you’re losing time or materials.

Invest in people and technology together. The US business growth trends show that companies succeeding with automation in US factories also invest heavily in training. When workers understand the new systems and see how it makes their jobs easier (not eliminates them), adoption goes much smoothly.

Build US supply chain resilience strategically. You don’t have to bring everything back onshore immediately. Start by identifying your most critical components and developing backup suppliers. Some companies are using a “China plus one” strategy, keeping some offshore production but adding domestic or nearshore options.

Look at financing options. Many states offer grants and tax incentives for smart manufacturing USA investments. The federal government has programs through the Manufacturing Extension Partnership that provide free consulting and help access funding.

Join or create industry networks. The most successful businesses I see aren’t doing this alone. They’re part of industry groups, sharing best practices, and sometimes even sharing resources for things like workforce training.

The American manufacturing industry isn’t dying—it’s changing. Companies that adapt methodically, focus on real ROI, and balance technology with human expertise are thriving. The industrial market in the USA will reward businesses that can deliver quality products faster and more efficiently than ever before.

Your move doesn’t have to be perfect. It seems that it has to be forward.